Technology That Moves

ReAble Labs combines advanced materials, precise engineering, and intelligent control systems to create prosthetics that move naturally and reliably.

Micromotor-Driven Actuation

Our prosthetic hand uses precise micromotor-driven actuation for natural, responsive finger movement. Advanced electronics control each motor for lifelike motion and adaptable grip control.

Precise control: Individual micromotor actuation for each finger

Responsive grip: Adaptive force control for diverse tasks

Efficient power: Optimized torque transfer with minimal energy loss

Modular design: Simple electronics replacement without full disassembly

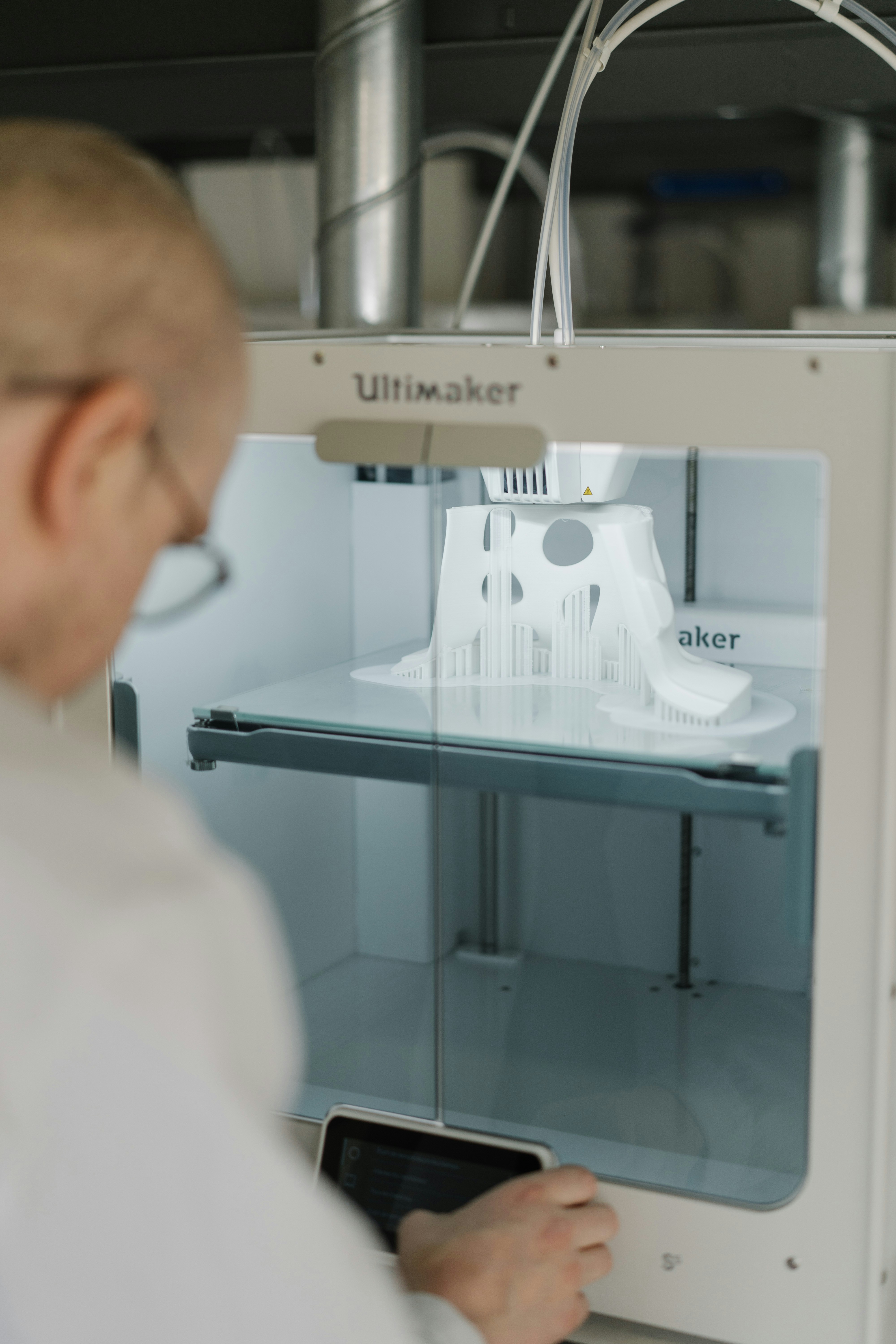

Why 3D Printing?

Additive manufacturing allows us to create lightweight, custom-fit prosthetics that adapt to individual users - all while maintaining strength and reliability.

Weight reduction: Internal lattice structures cut mass without sacrificing strength

Personalization: Every hand can be shaped to fit unique anatomy

Repairability: Damaged parts can be reprinted or replaced quickly

Rapid improvement: Design updates reach users faster through local production

Rapid prototyping of structural prosthetic components.

Signal & Control

Designed for flexibility - adaptable to various sensor and control architectures.

Control Interface

Compatible with micro-motor actuation, PWM control, and future myoelectric sensing.

Safety & Reliability

Built-in torque and movement limits designed to protect hardware and user comfort.

Expansion Ready

Modular electronics designed for firmware upgrades and new input methods.

Technical Overview

The full technical overview is currently in preparation. Specifications will be released as engineering validation progresses.

Prototype system. Specifications subject to change.

Disclaimer: ReAble's prosthetic systems are engineering prototypes not yet approved for clinical or commercial use.